Jobe Industrial offers a broad product offering of level switches, transmitters and gauges for a variety of fluids across an array of applications.

Illustrated Examples of Common Level Technologies

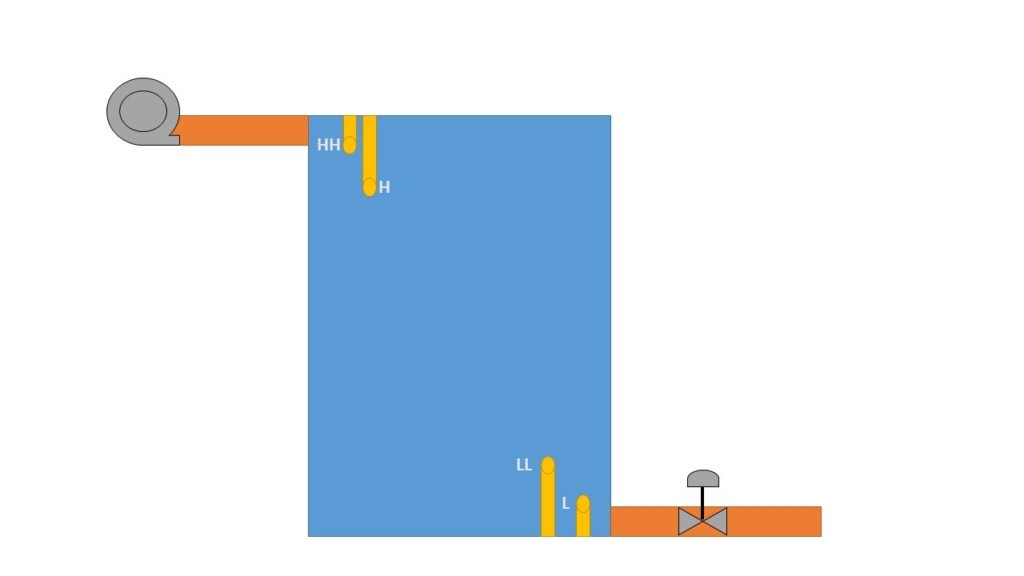

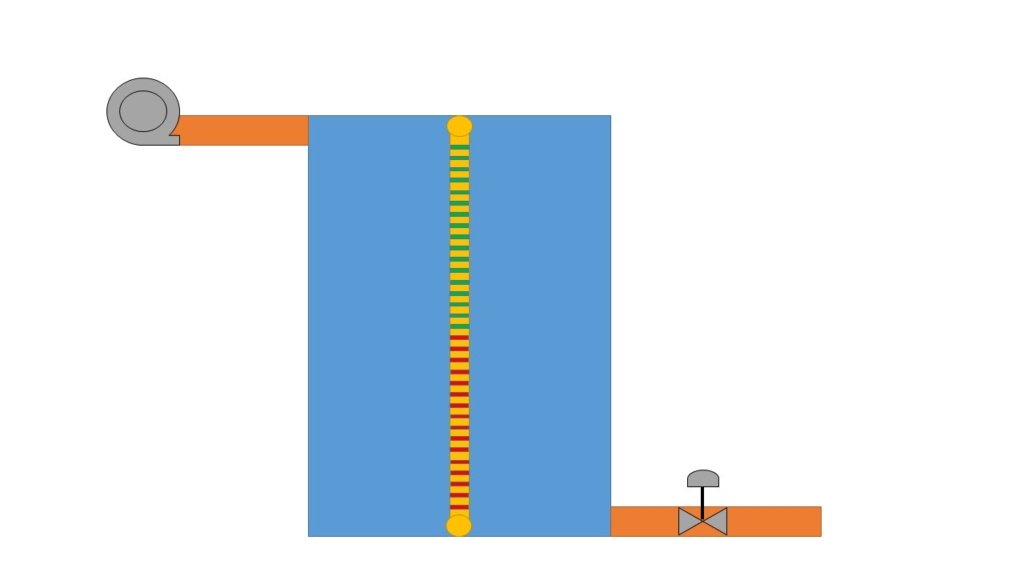

Level/Float Switches

One of the simplest and most cost-effective technologies for measuring level, level/float switches are used in liquid applications, with one or more set point per switch. Often used as High/Low level switches, systems can also be designed for use with High/High and Low/Low alarming set points for control.

Consisting of a mechanical float(s) moving up and down a rod or a radio frequency balanced impedance bridge, switches provide a digital signal output, either at the location or remotely, which can easily be inputted into a control or remote monitoring system.

Benefits:

Very cost effective

Simple to set up

Easy to use

Can be used as standalone devices (some have alarms built into them)

Manufacturers:

Babbit, Barksdale

Applications:

Water/Chemicals/Fuels

High/Low Level Alarm

Auto Tank Filling or emptying

Sump Controls

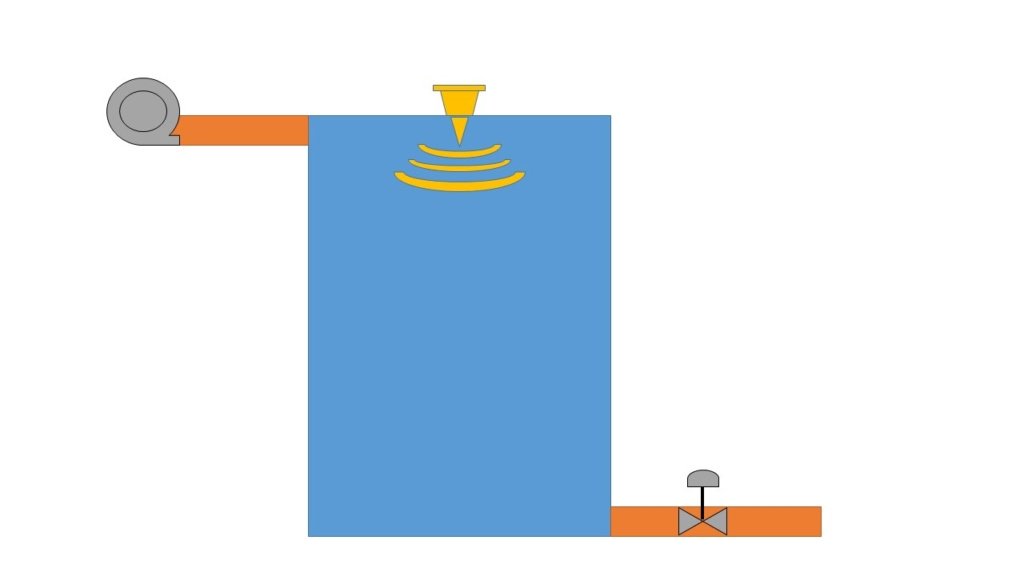

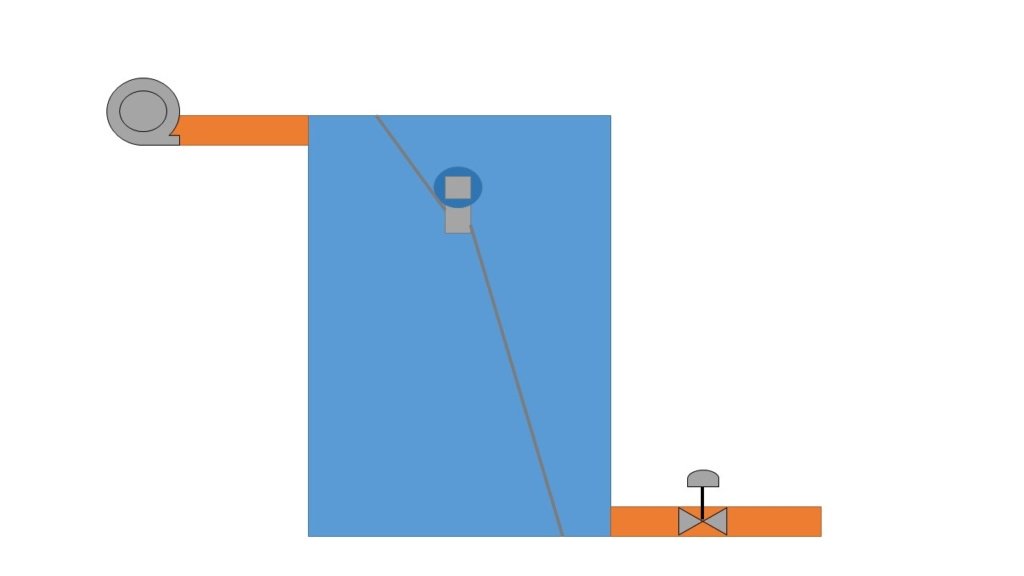

Pulse Radar

Also called non-contact radar, Pulse Radar technology is commonly used in difficult applications, often featuring multi-media material, where non-contact and high accuracy are important. An electronic pulse is directed at the fluid’s surface and then reflected back at the antenna, the round trip time is then calculated to determine the fluid level in the container. Providing an anolog output (4-20mA) as well as options for digital communications, the signal can be tied directly into a control or remote monitoring system.

Benefits:

Can measure any material with the dielectric constant greater than two

Measures multi-media material

Non-contact

High Accuracy

Most cost-effective on larger tanks

Manufacturers:

Babbit, Honeywell

Applications:

Water/Wastewater

Chemicals/Acids/Caustics

Slurries

Food and Beverage

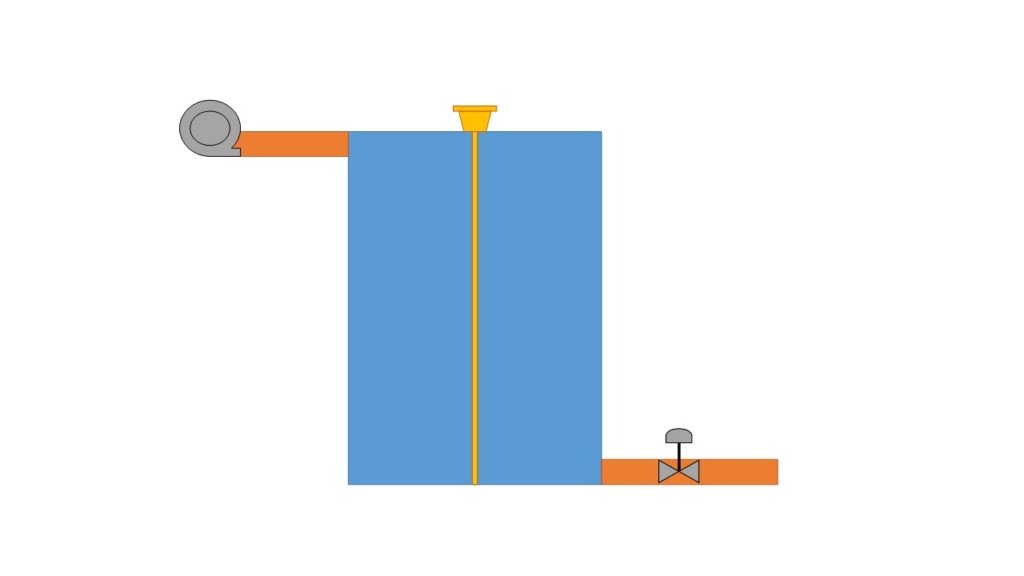

Guided Wave Radar

The go-to technology for tough applications, especially powder and oil and gas applications, as well as measuring in tight spaces. Guided wave radar sends a radar signal down a cable running the length of the tank and provides an analog (4-20mA) output signal for input into a control or remote monitoring system.

Benefits:

Can read materials with a very low dielectric number

Measures multi-media material

High accuracy

Remote mount electronics

Can measure hundreds of vertical feet

Manufacturers:

Babbit, Honeywell

Applications:

Accumulators

Extreme pressure variations or pressurized containers

Multi-use tanks

Liquefied gas containers

Items with low dielectric qualities

Raw materials and Polymer Powders

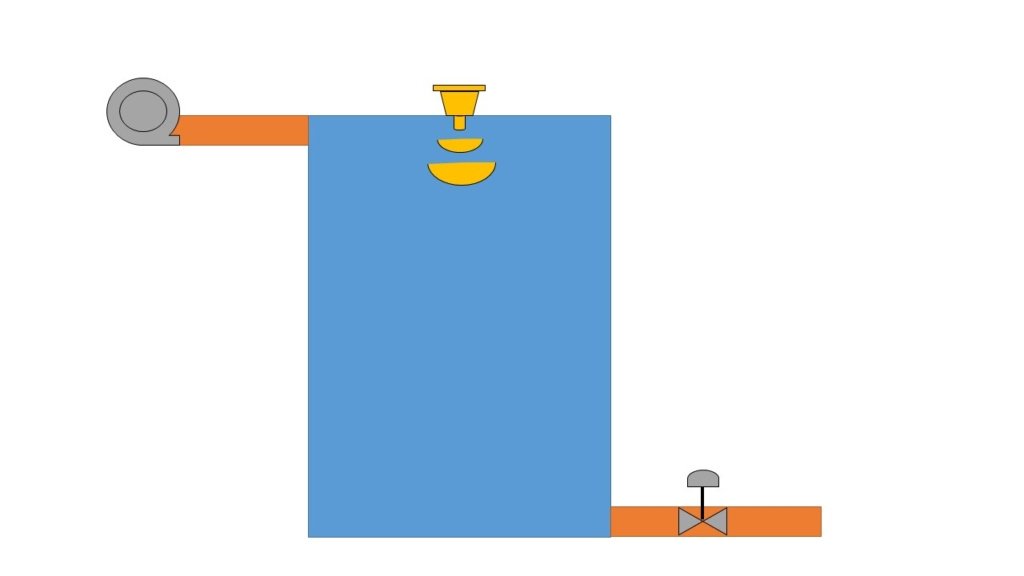

Ultrasonic

Ultrasonic level measurement is the most common, cost-effective, non-contact level measurement technology. By sending an ultrasonic wave toward the liquid surface, level can be reliably calculated by measuring the signals transit time. The analog output (4-20mA) signal can be inputted into a control or remote monitoring system. Different ultrasonic form factors are available for use in solid, liquid, and slurry applications.

Benefits:

Cost-effective solution

Reliable accurate

Non-contact

Ease of installation and reduced maintenance

Self-contained, battery powered, wireless units available

Manufacturers:

Babbit, Banner, Honeywell, Turck

Applications:

Water/Wastewater

Chemicals/Oils

Viscous Fluids/Slurries

Food and Beverage

Solids

Level Sight

Commonly used in non-critical applications, Level Sight or Sight Glass is mounted to the exterior of a tank and ensures reliable, real-time visualization of a tank’s level.

Benefits:

Inexpensive

Direct read

Good visual back-up

Measures most liquids

Manufacturers:

Babbit, Barksdale

Applications:

Most liquids

Differential Pressure Transmitter

Using one externally mounted transmitter, differential pressure level technology compares the differential pressure reading from the top or “head” of the tank to the one at the bottom of the tank. Due to the precision of pressure measurement, the calculated level is very accurate and highly precise. An analog (4-20mA) output signal, as well as other communications protocols are offered for use in a control or remote monitoring system.

Benefits:

Very accurate

Tank size and shape are not as important

Cost effective

Can measure most liquids

Manufacturers:

Honeywell, Wika

Applications:

Pressurized or open air tanks

Liquids or Light Slurries with a diaphragm

Water/Wastewater

Chemicals/Oils

Food and Beverage

Suppliers

Applications