Turbine and mag meters use different technologies to effectively measure flow in HVAC systems. Both have been used for many years and are proven to be reliable and accurate flow meters. However, there are a few notable differences to consider when selecting the best meter for your application.

How Do They Work?

Both meters are inserted directly into the flow and feature hot tap installation and removal without system shutdown. Turbine meters calculate the volumetric flow by measuring the speed of the meter’s turbine rotations in relation to the size of the pipe. Insertion mag meters electrically generate a magnetic field within the flow. Using Faraday’s Law, the meter senses the voltage signal generated by the conductive fluid (required) flowing through the magnetic field – the higher the voltage the faster the flow.

The Main Differences

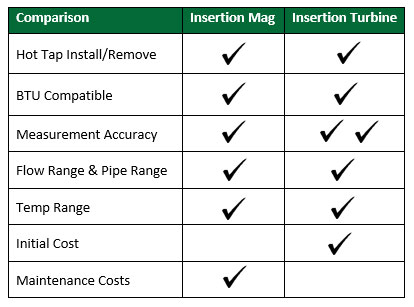

While there are differences, insertion turbine and mag meters are both commonly used throughout HVAC systems. Specifications vary from model to model (see links to product specific information below), but for the purposes of this article here is a simple chart outlining their differences.

As you can see, both meters have their plusses and minuses. Therefore, selecting the right one for your application depends on the system’s specifications and what is most important to the end user.

Not on the price or spec sheets and often overlooked, maintenance costs and life expectancy are real costs to consider when deciding which meter technology to use. Over time HVAC hydronic systems pick up sediment and develop scale in the flow stream, taking a toll on instruments with moving parts. As a result, turbine meters are going to require frequent maintenance and face decreased accuracy over time. However, without any moving parts, mag meters don’t face the same maintenance requirements leading to reduced maintenance cost, fewer headaches and an increased life expectancy.

In conclusion, both meters are an excellent choice for HVAC systems, but taking a moment to review your project or customer’s priorities, in addition to the required specifications, will help you to select the best meter for the job. Assuming both meter technologies can meet the specification for accuracy (if neither can, its best to look at inline mag meters), then the decision really comes down to cost priorities. If the project is focused on upfront costs, then selecting a turbine will be the right choice. However, if total cost of ownership, including reduced maintenance time and costs, are a priority, then an insertion mag meter is going to be the best option.

Suppliers

Products

Onicon F-3500 Flow Meter

Each ONICON’s F-3500 Insertion Mag Meter provides a single analog output for flow rate, a high resolution frequency output to drive peripheral devices, a scalable pulse output for totalization and an empty pipe alarm system.

Onicon F-1000 Flow Meter

ONICON’s F-1000 Series Turbine Flow Meters are individually configured and wet calibrated to your application.

Onicon F-3500 Flow Meter

ONICON’s F-3500 Insertion Electromagnetic Flow Meter or F-1000 Insertion Turbine Flow Meter easily combine with the System-20 BTU Meter to create an energy measurement system with unsurpassed accuracy and reliability